COMPANY

With a dedicated team of highly experienced employees, we try to push the limits of our imagination to get the best problem-solving ideas. At Transpak we think, that a solution is a mutually agreed-upon answer to a recognized problem. Therefore, our customers and the obstacles in their way to success, stand at the core of our focus.

In the process of bringing a solution to life, we have a team of project managers, engineers and technicians who have years of experience and know-how, especially in food and beverage industries, as well as other industries. Together with our respected partners, we deliver a complete technical and commercial solution in the form of turnkey projects for complete bottling lines and end-of-line packaging systems as well.

Our commitment to continuous development of project management organization and company culture will enable us to meet all customer requirements on time, within agreed specification and on budget.

SOLUTIONS

YOUR PROBLEM IS

CHALLENGE FOR OUR TEAM

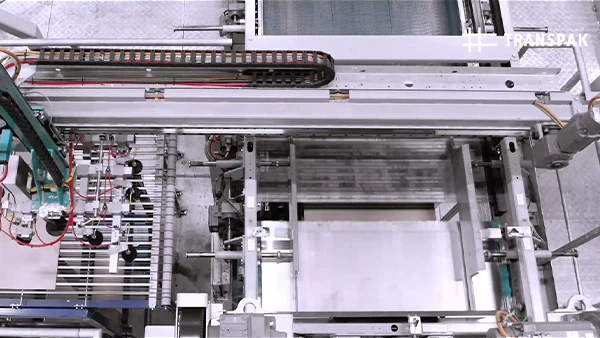

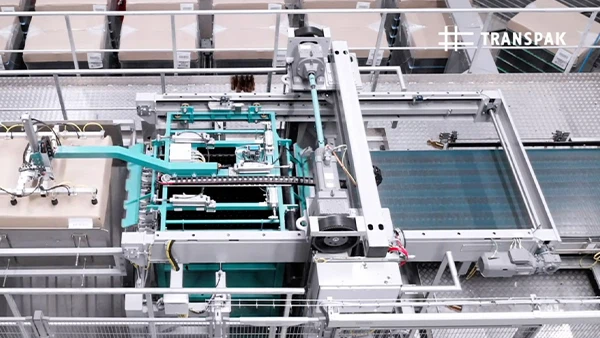

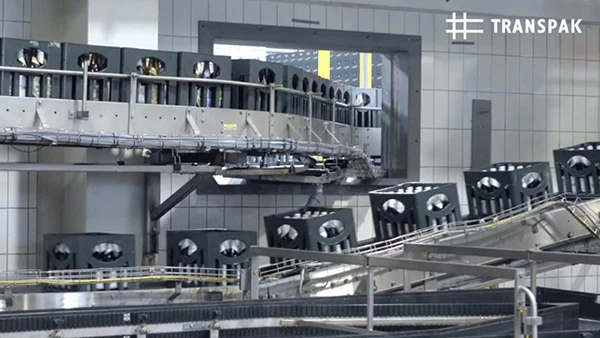

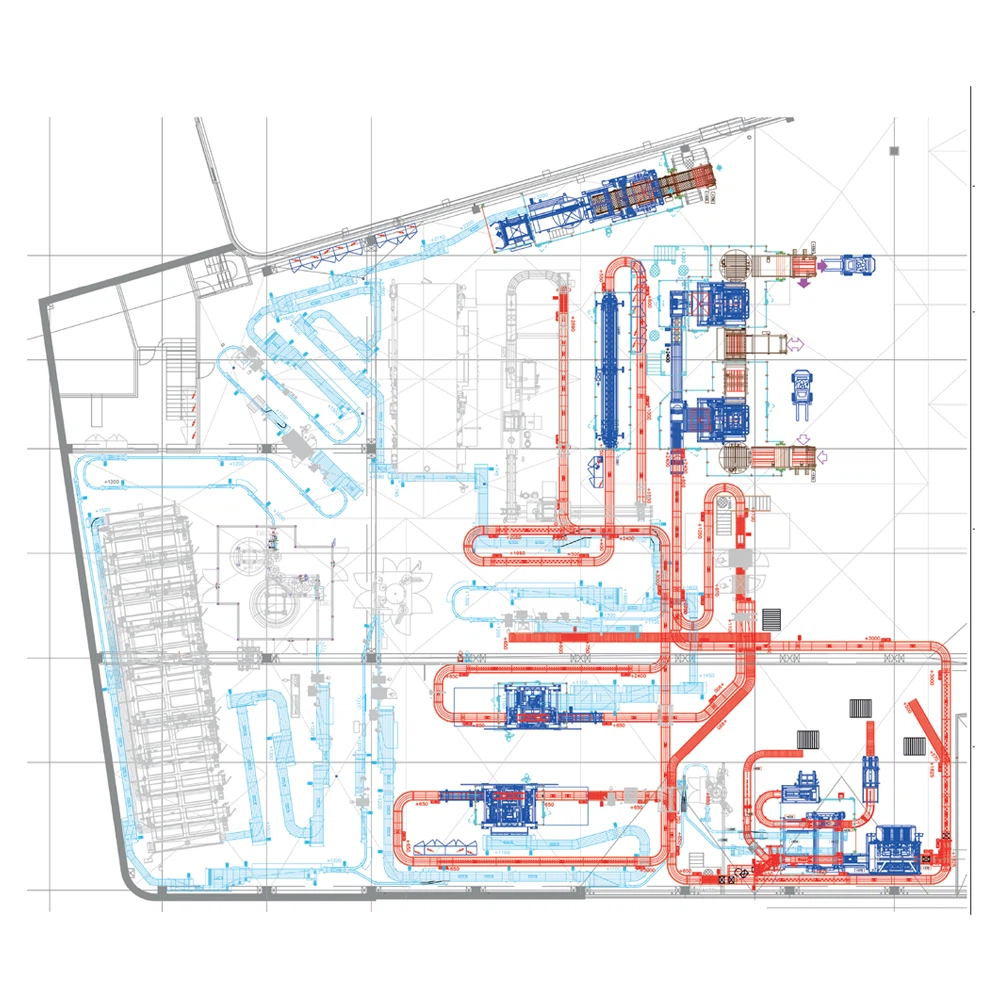

SOLUTIONS FOR COMPLETE PACKAGING LINES

Transpak is specialized for integration of complex packaging lines, our activities has a range from packaging line audits to project management, and entire line automation. We offer custom made line upgrades, packaging line relocations and safety audits as well. Our in-depth training programs ensure a smooth on-site line commissioning.

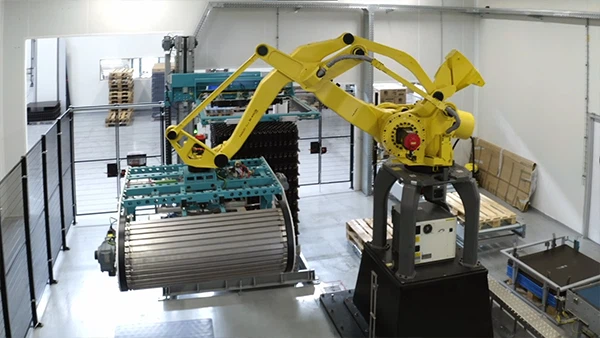

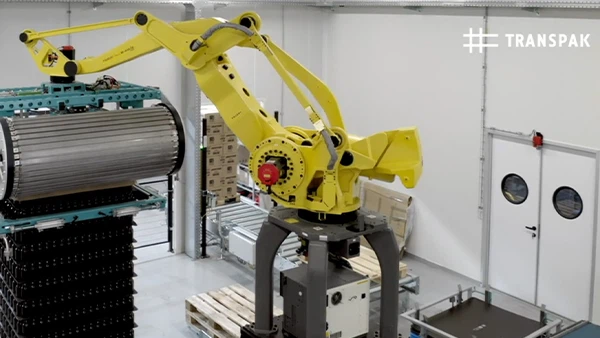

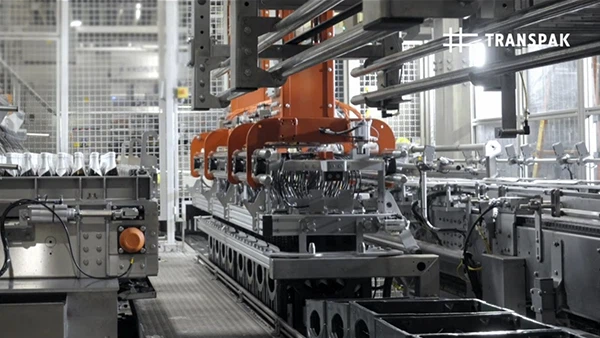

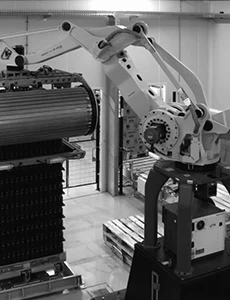

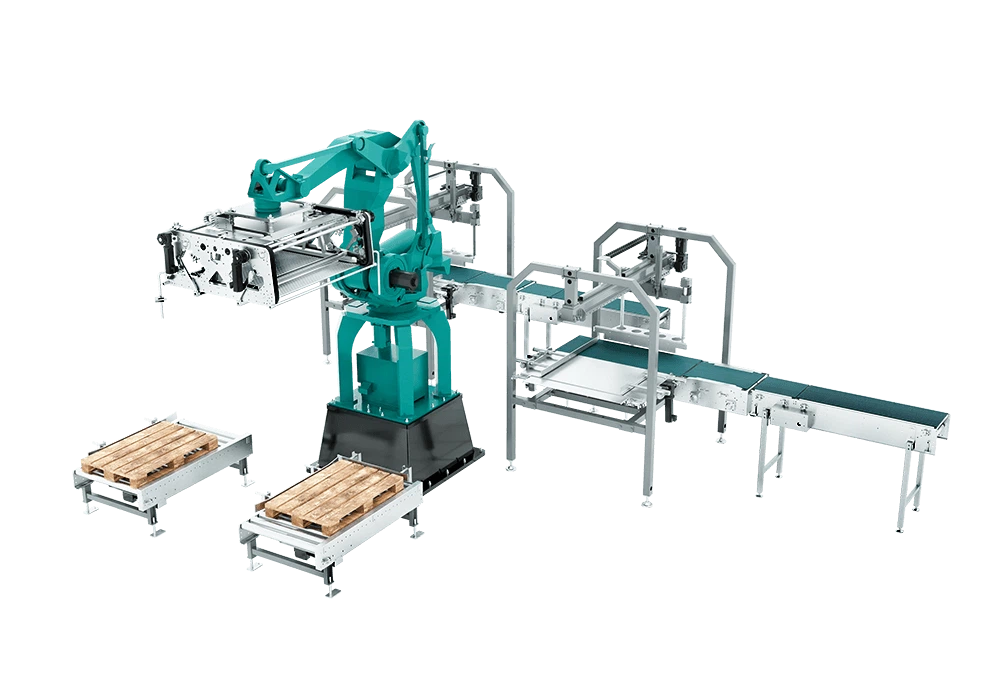

SOLUTIONS FOR ROBOT GRIPPER HEADS FOR MULTIPLE APPLICATIONS

Our custom made robot solutions are based on flexible and portal robots. Range of our innovative head solutions covers from shutter, clamping, vacuum, and/or magnet heads executions as well. Robot applications are best suited for low and up to middle capacities.

Applications for cartons, crates, bottles, cans, packages, kegs.

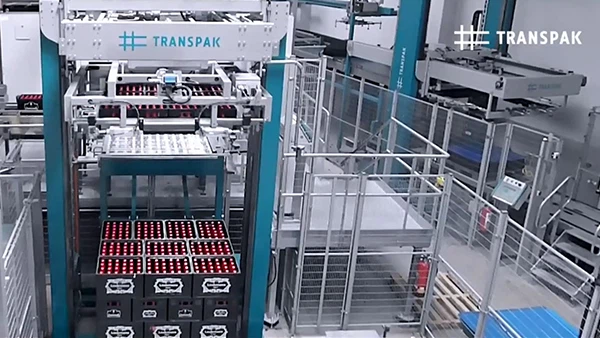

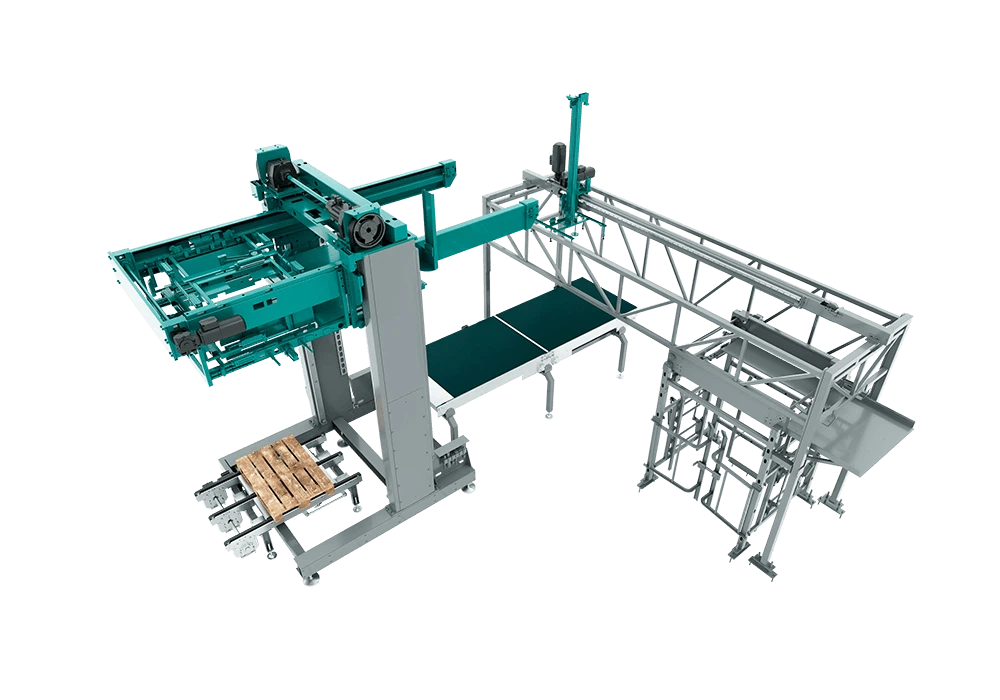

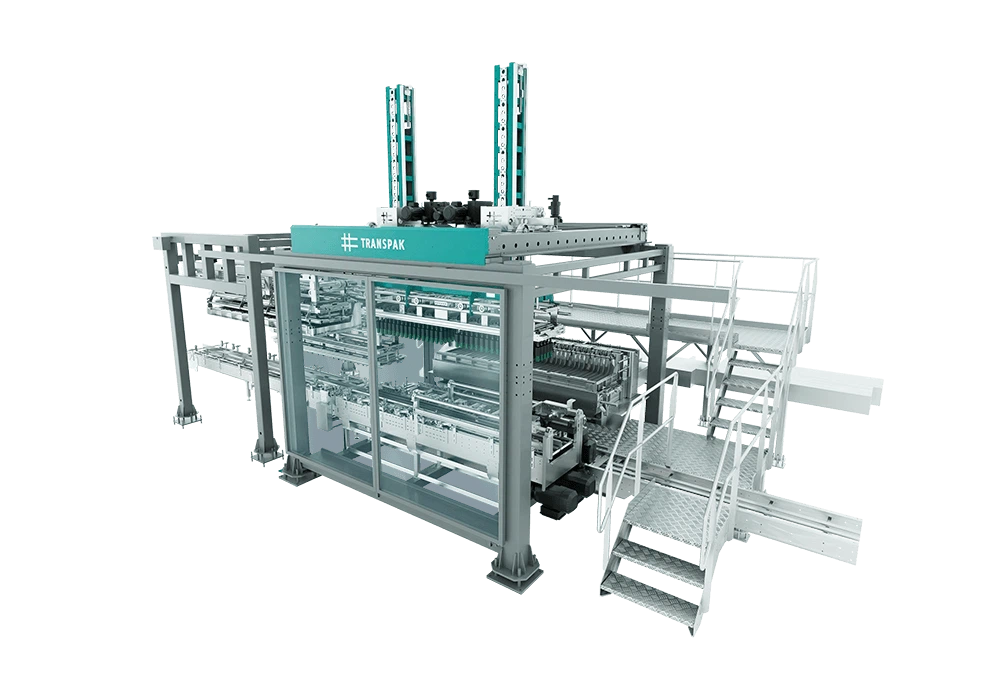

SOLUTIONS FOR UNIVERSAL PALLETISATION

With multiple product in-feeds (single lane, double or tripple lane and in-line with robotic layer formation as well) capacity up to 450 layers per hour could be realised. With our Universal Palletiser Royal U and Royal UH we are capable to solve all challenges up to the highest capacity range. Our machines are for 24/7 production designed.

Applications for packs, trays, boxes, crates.

SOLUTIONS FOR CRATE PALLETISING AND DEPALLETISING

Our solutions for crate depalletizing and palletising are executed for different kind of product in-feed and discharge, depended on requested capacity, applicable for line capacities up to 500 layers per hour. We have gripper head solutions for every product. Our machines are designed for 24/7 production.

Applications for crates and kegs.

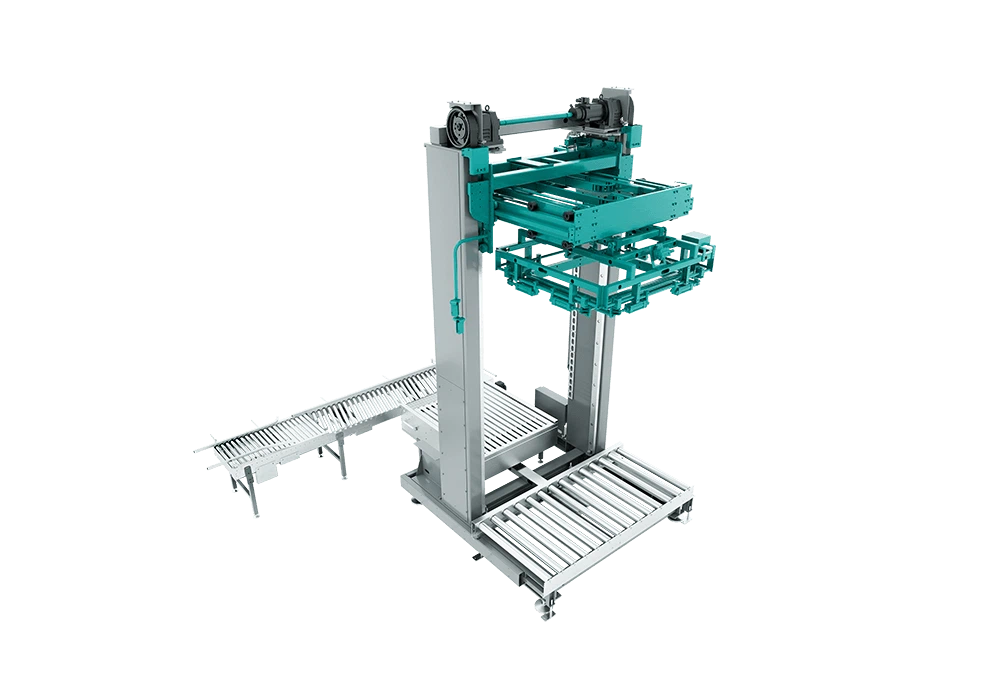

SOLUTIONS FOR CAN AND GLASS DEPALLETISING

With our sweep-off depalletiser solutions you can manage glass, cans and also PET products. With low or high level discharge Royal B up to 180 layers per hour. With high level discharge Royal BH up to 300 layers per hour.

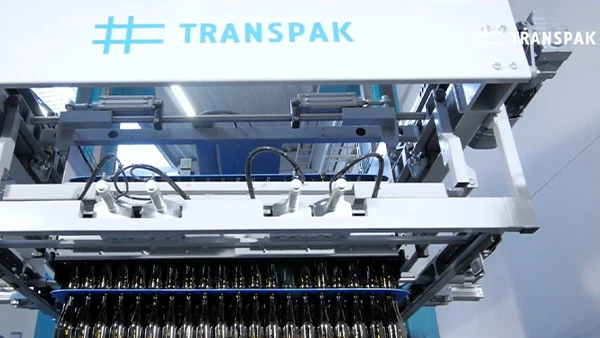

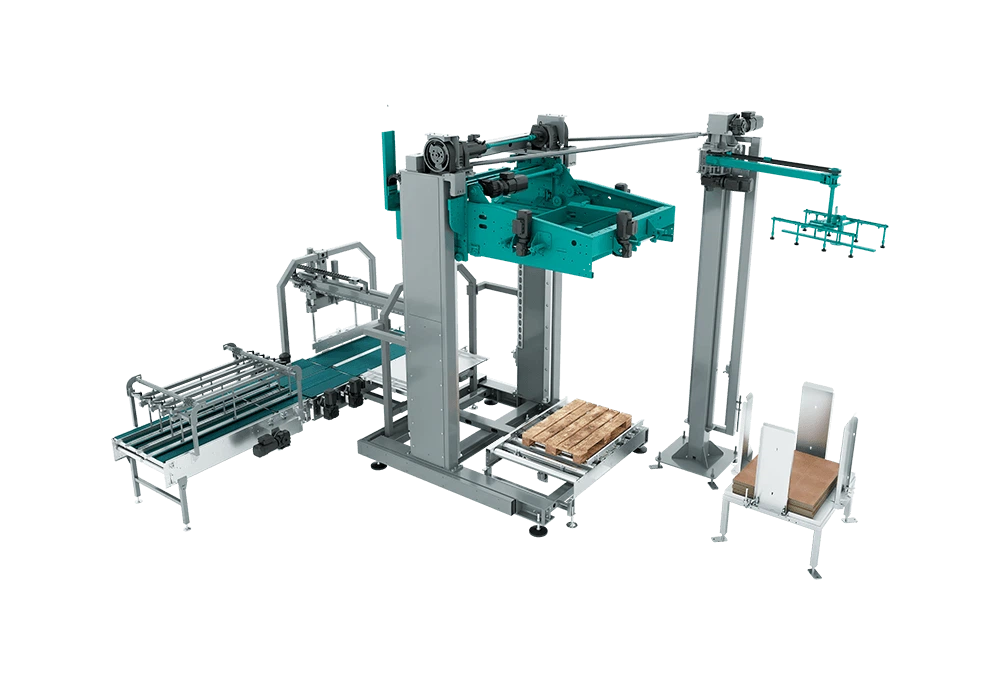

SOLUTIONS FOR CRATER AND DECRATER

Transpak solutions for crater and decrater are designed for capacities up to 500 cycles per hour.

Our solutions for Craters and Decraters (PORTAL C & PORTAL D) are in range from one up to ten heads with crate feeding in one or two tracks with execution to insert multipacks in crate or american carton. According request we have multiple head executions with coresponding gripper head magazine for semi or fully automatical gripper head exchange. Our machines are designed for 24/7 production.

Applicable for bottles and multipacks in crates and carton.

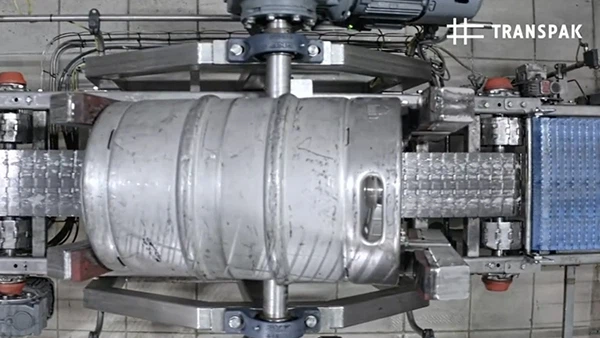

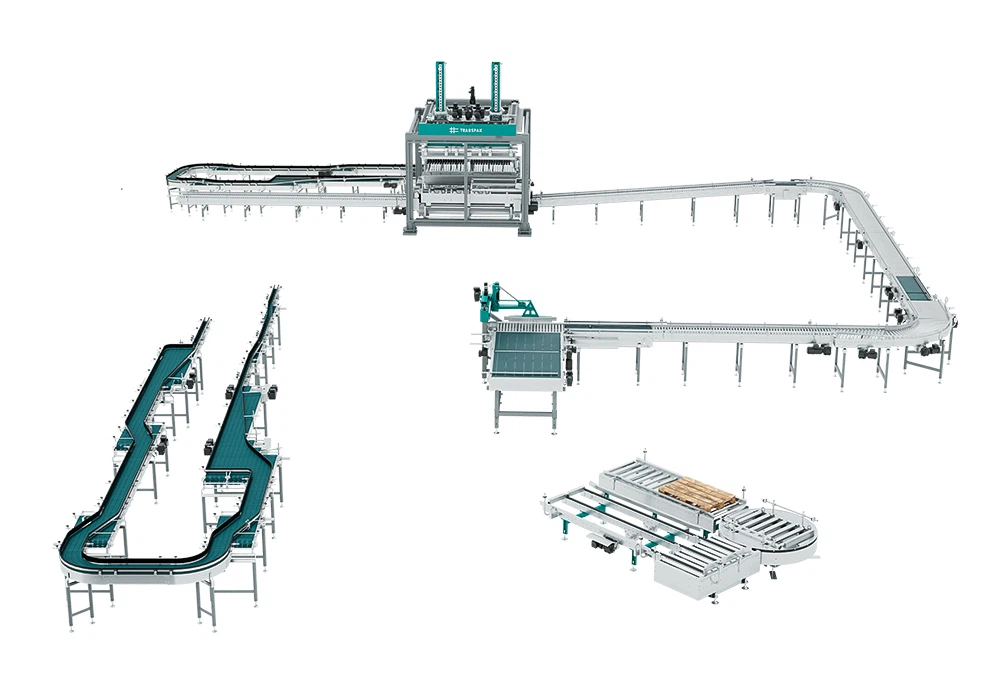

SOLUTIONS FOR CONVEYING CANS, BOTTLES, TRAYS, PACKS, PALLETS AND KEGS

Transpak conveyor systems have a modular structure and as such can be used in any area of application. All conveyors are robustly built with high quality components. The container conveyor is constructed in a clean design with open drive and return station. Container and pack conveyors are equipped with energy-saving PM gear drives.

Applications for pallets, packs, trays, crates, kegs and different containers.

VIDEOS

OUR DEDICATED

SOLUTIONS IN

PRACTISE

CONTACTS

OUR TEAM OF PROFESSIONALS

GUARANTEE

KNOWLEDGE,

EXPERIENCE AND CREATIVITY